surface grinding machine ppt

Grinding Machines Grinding Grinding is a surface finishing operation where. It is basically a finishing process employed to produce high accuracy and surface finish.

Ad Kremin Inc has the full spectrum of manufacturing capabilities - including grinding.

. Vertical spindle and rotary table type Horizontal spindle surface. Introduction A grinding machine often shortened to grinder is any of various power tools or machine tools used for grinding which is a type of machining using an abrasive wheel as the cutting tool. Flaring Cup The flaring cup wheel type number 11 is commonly used for tool grinding.

This machine tool is used to grind or mill the connecting plane of the engine block and cylinder head. According to the quality surface finish. Large Selection and Fast Shipping.

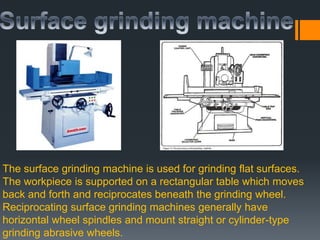

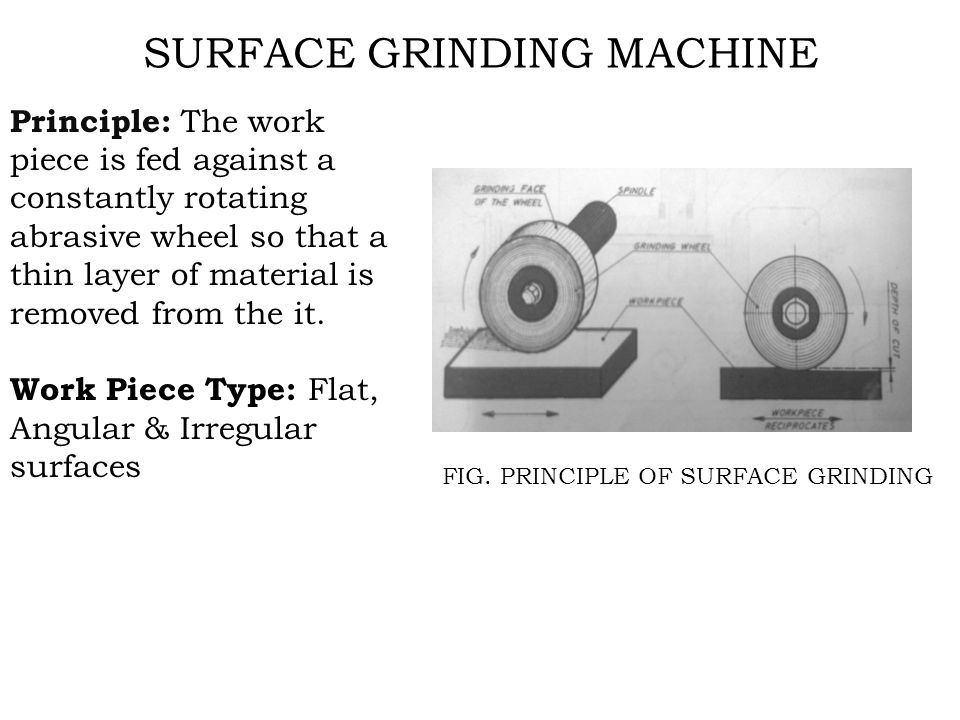

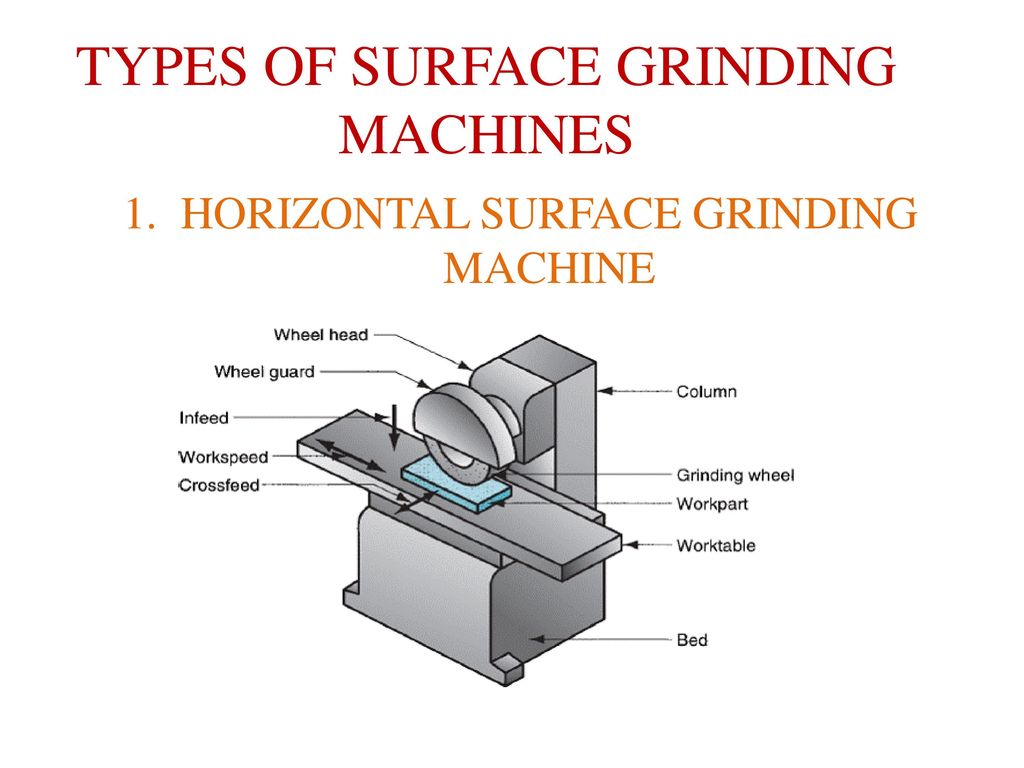

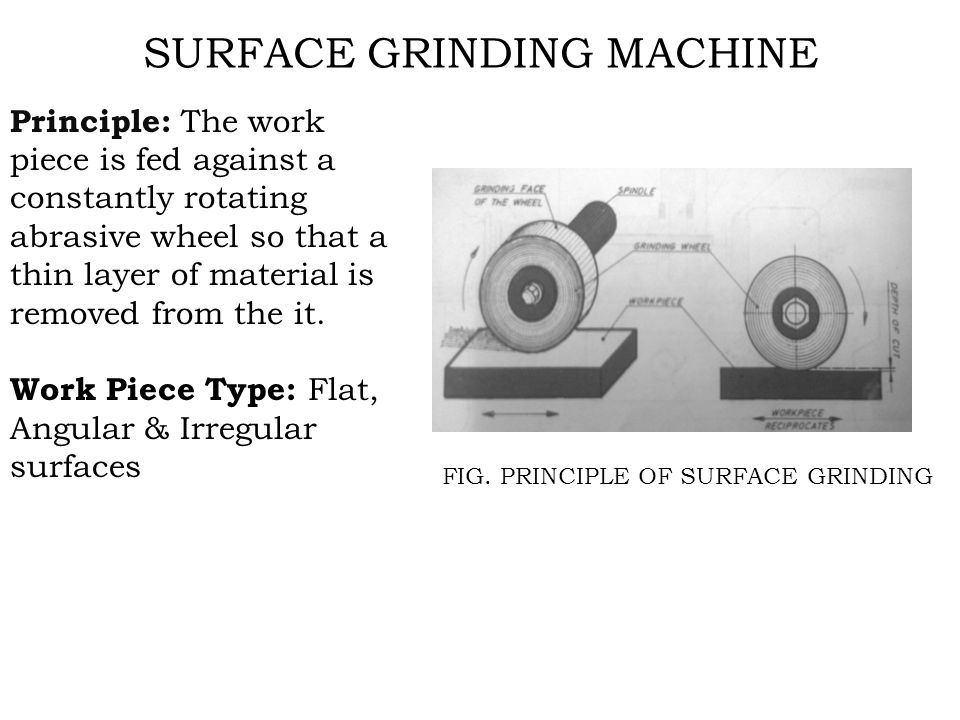

Surface grinding machine generally consists of a base table. The work piece is fed against a constantly rotating abrasive wheel so that a thin layer of material is removed from the it. It is a very precise tool which uses a stationary abrasive rotating wheel to shave or finish a metallic surface which is held in place by a vise.

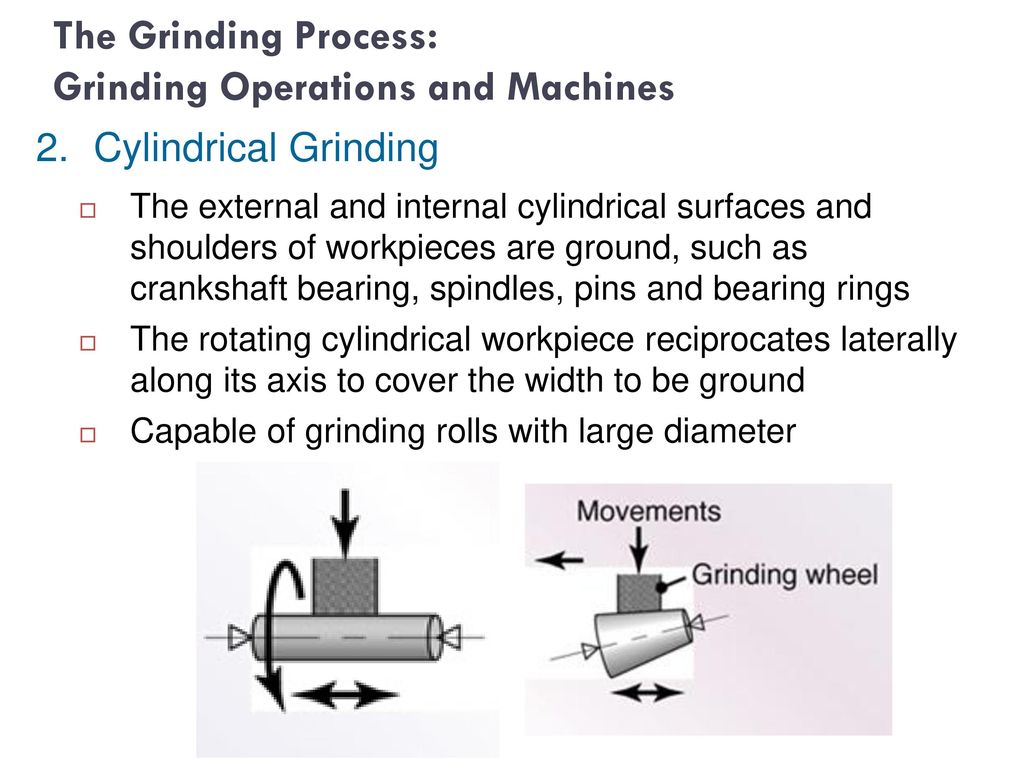

Broadly there are two different types of cylindrical grinding machine as follows. This machine is a vertical grinding and milling machine with high grinding efficiency and accurate. Flat Angular Irregular surfaces 8.

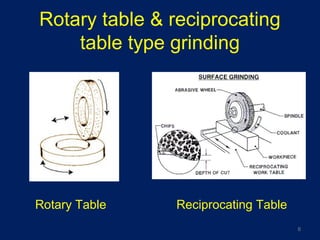

Vertical spindle and reciprocating table type 4. With a resinoid bond it is useful for snagging. There are four different types of surface grinders.

Horizontal spindle and rotary table type 3. Precision grinder Cylindrical surface internal tool cutter disc thread cam shaft grinder 4. PRINCIPLE OF SURFACE GRINDING Principle.

Crankshaft Grinder Machine and Crankshaft Grinders - The Crankshaft grinding equipment is a light-weight portable and can be quickly transported to any site all over the world. TYPES OF CYLINDRICAL GRINDING MACHINE This machine is used to produce external cylindrical surface. The Surface Grinder is mainly used in the finishing process.

Cnc Grinding Machine PowerPoint PPT Presentations. SURFACE GRINDING MACHINE FIG. Types of grinding Machine Grinding machines according to quality of surface finish may be classified as 1.

Ask shop staff to demonstrate proper use of this tool. Metal Cutting Manufacturing Processes Outline Metal Cutting Chip Formation Processes Control Conditions Back rake angle Shear angle Chip Formation Continuous formation Built up edge formation Discontinuous formation Effects Chip formation Shear angle Chip Formation Processes Shaping Turning Milling Drilling Sawing Broaching Grinding Machining Operations Machining. There are several types of grinding machines such as surface grinders bench grinders cylindrical grinders tool and cutter grinders jig grinders gear grinders profile.

MSC Industrial Supply Co serving the metalworking safety and MRO fields for 75 years. ONSITE CRANKSHAFT GRINDING MACHINE 1 - in situ crankshaft grinding portable crankshaft grinder onsite crankshaft grinding machine crankshaft grinder machine Email us. In this process by holding work piece on the table by the surface or perimeter of rotating grinding wheel material can be removed by the abrasive grinding action is used in surface grinding.

Roughing and finishing flat cylindrical and conical surfaces. We manufacture the crankshaft grinding and repair machines having a range from 35 mm to 700 mm. Rough Non-precision grinding 2.

View Grinding Machineppt from MECHANICAL 123 at Nirma University Ahmedabad. Advent of advanced grinding machines and grinding wheels has elevated the status of grinding to abrasive machining where high accuracy and surface finish as well as high material removal rate can be achieved even on an unhardened material. Tool rests on bench or pedestal grinders shall be set no more than 116 inch from the wheel.

Rough grinder Floor and bench swing frame portable abrasive belt grinder 2. There are several types of grinding machines such as surface grinders bench grinders cylindrical grinders tool and cutter grinders jig grinders gear grinders profile grinders and special purpose grinders. PowerPoint PPT presentation free to view What are Best Grinding Wheels for Metal - A grinding wheel is an associated abrasive material-based cutting tool.

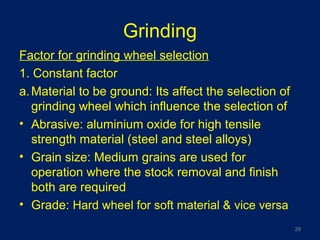

The grinding wheel consists of sharp crystals called abrasives held together by suitable bonding. Equipped with corresponding fixtures it can also be used for plane processing of other parts. A grinding disc is a sharp cutting tool with thousands of cutting edges on the side of the surface.

SURFACE GRINDING MACHINE This machine may be similar to a milling machine used mainly to grind. Precision grinding RoughNon-precision grinding To remove more stock than other grinding aFloor stand and bench grinders bPortable and flexible shaft grinders cSwing frame grinders dAbrasive belt grinders. Ad Explore a Wide Range of Surface grinding process at MSC.

Horizontal spindle and reciprocating table type 2. 1Plain centre type cylindrical grinder 2Centre type universal grinder 9 10. Rotary metallographic grinding machineppt - This report studies sales consumption of Rotary.

WORKING PRINCIPLE OF surface grinding PROCESS 5. Contact RA Power Solutions. The bulk grinding wheel workpiece interaction as given in Figure 2 can be divided into the following.

Dish The chief use of the dish wheel type number 12 is in tool work. Finishing internal cylinders or bores. Grinding Safety Guidelines 1.

The surface grinding is a special type of grinding process. Abrasive wheel machinery shall not be operated without the appropriate guards in place. CNC Gantry Machine CNC machine.

Its face may be plain or beveled. Ad Metalworking Machinery Tooling and Accessories for All Industrial Shop Needs. This vise which is part of a table or carriage is.

Grinding Classification of grinding machine. Orders Ship Deliver Fast. The grinding machine is used for 1.

One Year Warranty and Lifetime Technical Support. The main performance characteristics. The surfaces may be straight tapered steps or profiled.

Each grain of abrasive on the wheels surface cuts a small chip from the work piece via shear deformation. Surface grinding machines are employed to finish plain or flat surfaces horizontally vertically or at any angle. Plain or beveled faces are available.

Special training is required before using the surface grinder. Advanced manufacturing in high precision parts. Surface grinding but can also be used for offhand grinding of flat surfaces.

Hydraulic Circuit For Milling Machine Explained In Details Engineering Arena

Hydraulic Circuit For Surface Grinding Machine Explained In Details Engineering Arena

Surface Grinding Operations Ppt Download

Grinding Machine Ppt Quality Assurance Cesinaction Org

Ppt Grinding Powerpoint Presentation Free To View Id 170922 Zdc1z

Mechanism Of Grinding Process Download Scientific Diagram

Surface Grinding And Accessories

Milling Grinding Machines Ppt Video Online Download

Design And Fabrication Of Low Cost Surface Grinding Machine Ppt Download

Ppt Grinding Powerpoint Presentation Free Download Id 2175456

Grinding Machine Interview Question And Answers

Grinding Ppt Video Online Download

Grinding Ppt Video Online Download

Chapter 9 Material Removal Processes Abrasive Machining And Finishing Operations Ppt Download